Assignment 04 Electronic Production

Objectives of the week

- Characterize the design rules for your PCB production process.

- Understand SRM-20 machine.

- Understanding of design rule.

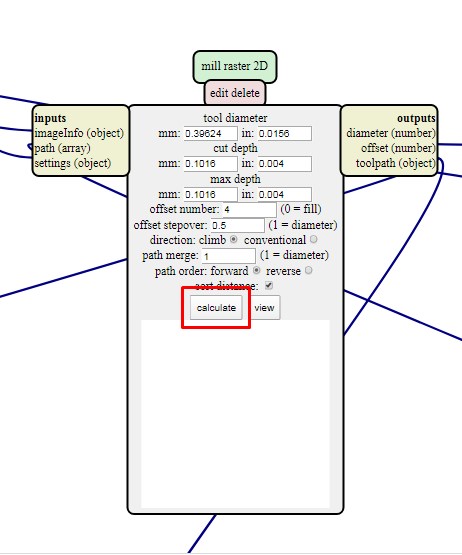

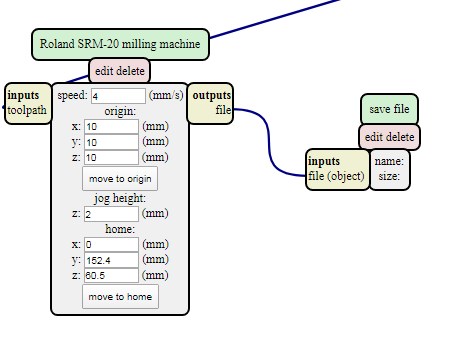

- Understanding MOD

1. Group assignment

Learning outcome

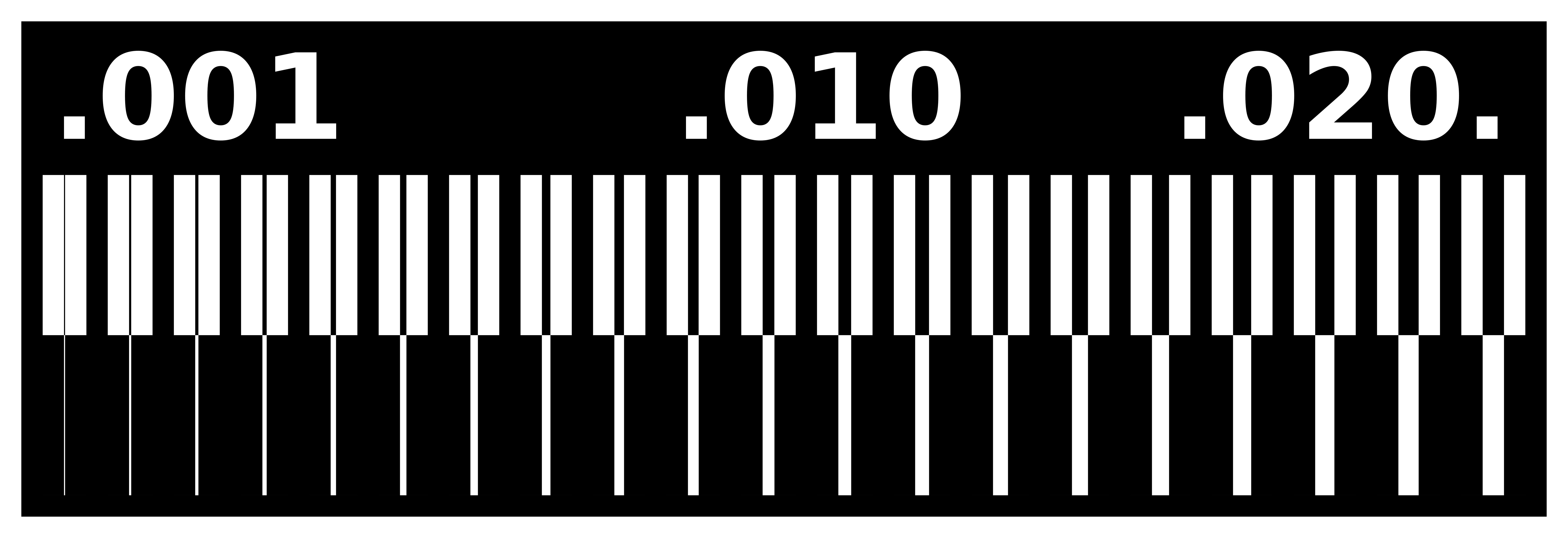

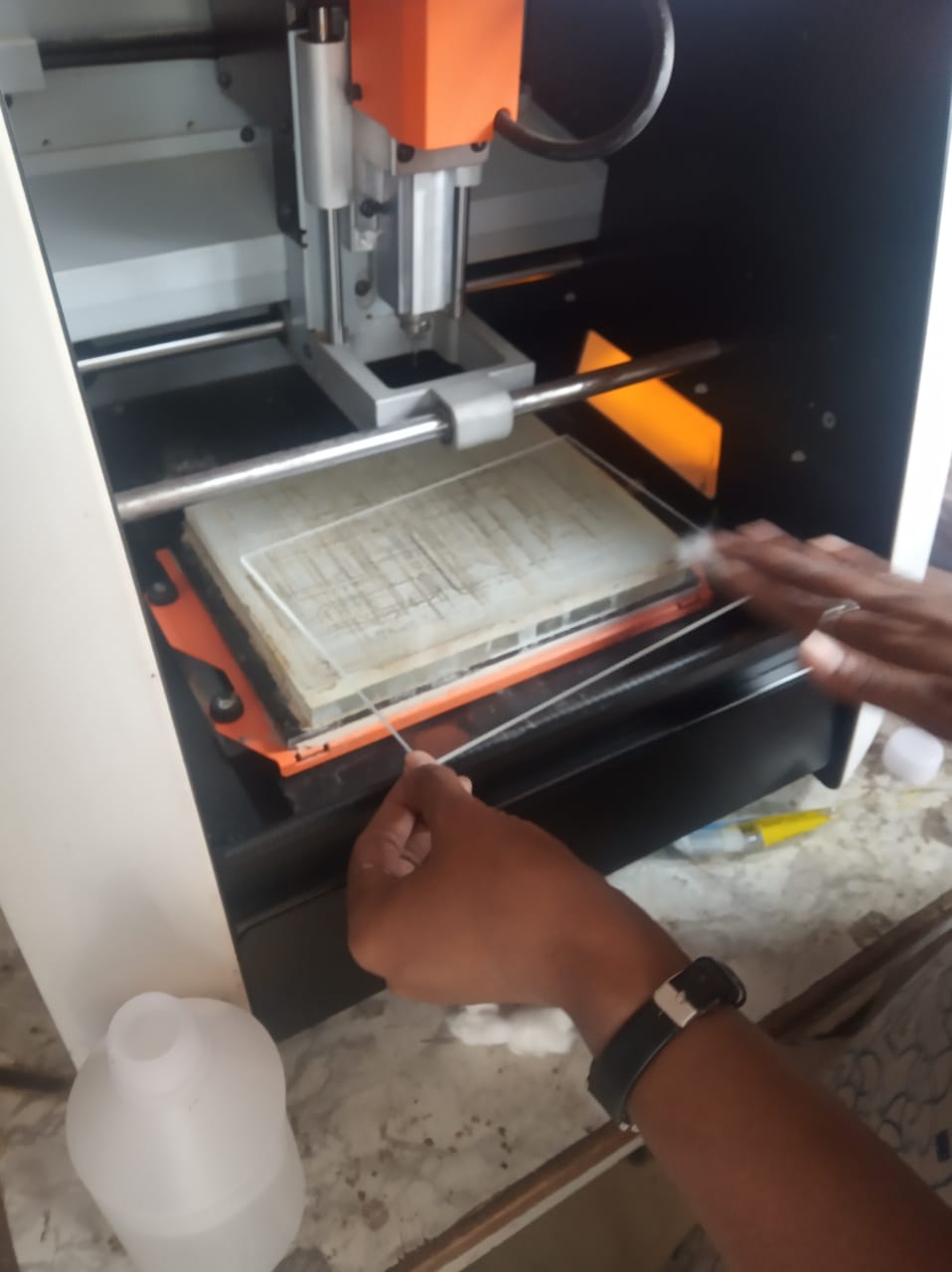

In group assignment, the task for this week is to characterize the design rules for PCB production process. So we five member in group, trying to machining of PCB using SRM-20 i.e. PCB milling machine available in our Fab Lab. So, lets see how we develop the PCB. The given png image for trace and cut is shown below:

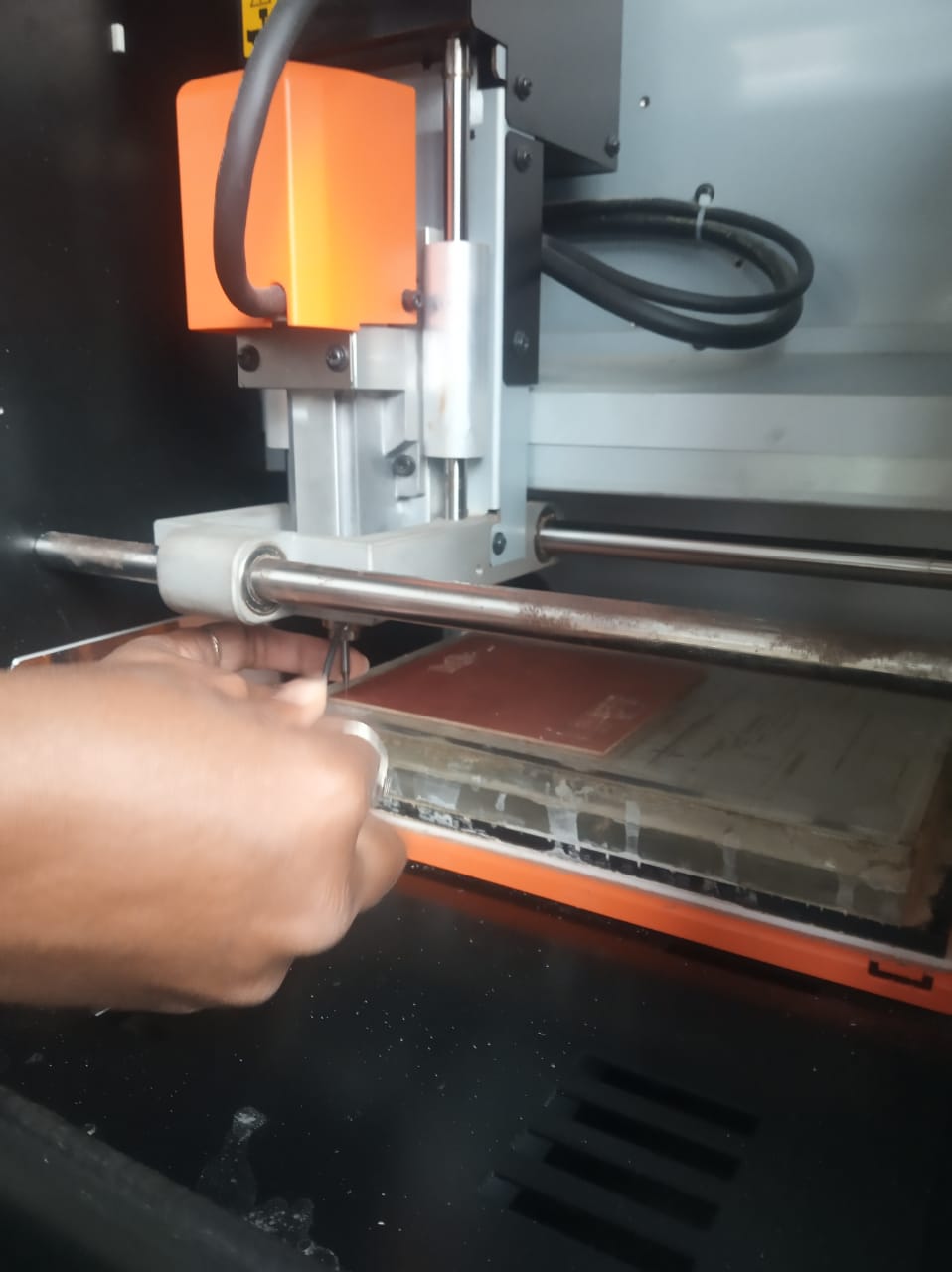

The file is converted into rml format by using the modes. How the modes are used, it is given in Individual Assignment. For PCB trace operation we are use 1/64inch drill bit. The machine bed is cleaned by Acetone chemical. Then the PCB is pasted on bed of machine and started the machining. After tracing next operation is cutting. The cutting file is selected for this operation. Drill bit changes, now 1/32-inch drill bit is used and cuted the PCB.

|

|

|

|

|

|

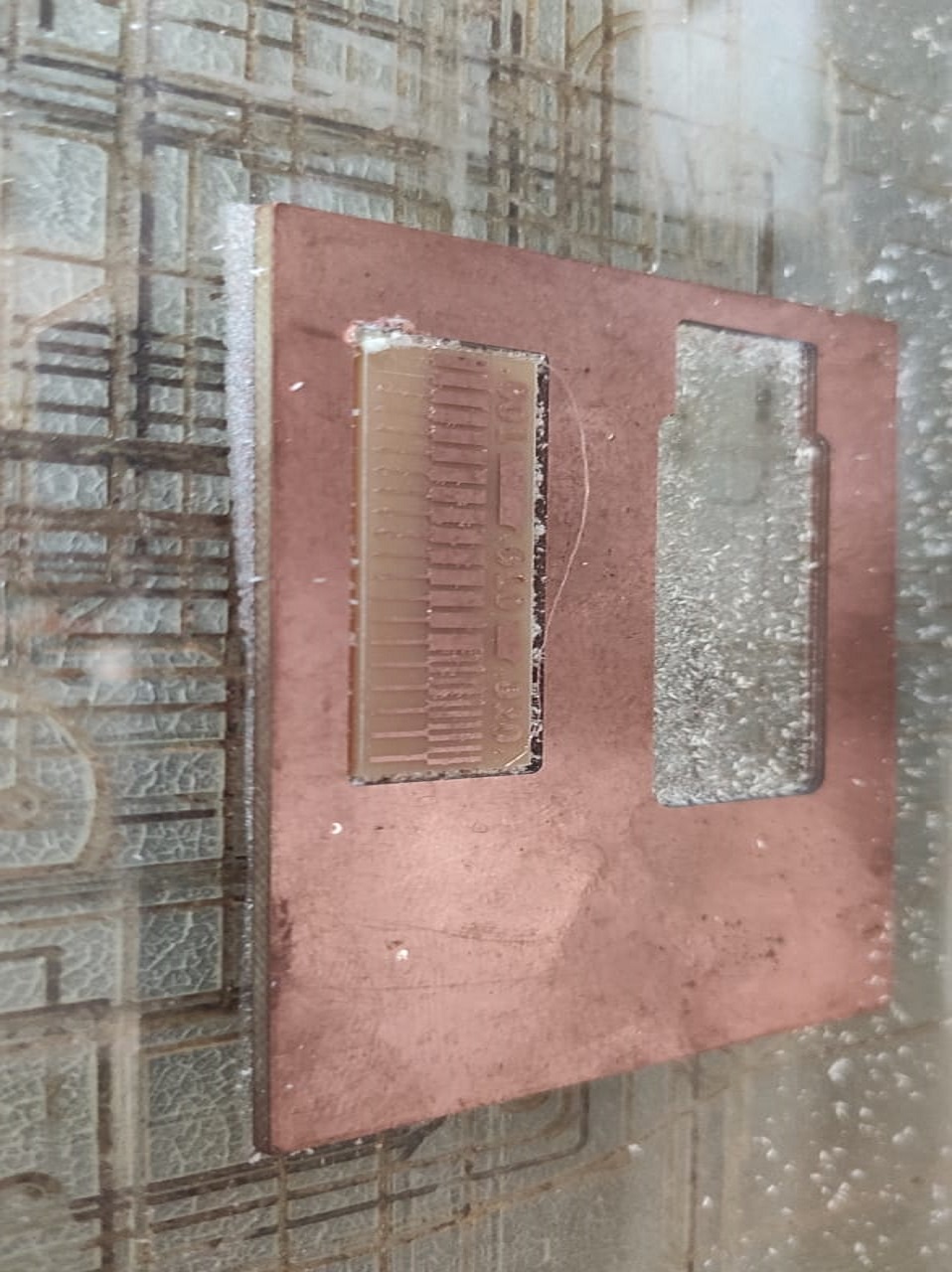

Here the line test is conducted between the 0.001 mil to 0.020 mil. The line widths around .001 mil are bit risky to mill, but the ones nearer to 0.01 mil are quite good and line around 0.020 are good to machining.

When you are fitting the board with double-side tape to the wooden surface be sure to press it really strongly! Sometimes it’s a good practice to clean the wooden plate from rests of the previous tapes, or even hardly visible glue. Due to uneven pasting, the bubble is form to the back of PCB material, it will affect to machining, sometimes it fails to machining also. Also, it’s also needs to check the bed level, it’s also effects on machining. The bed should be perfectly horizontal. So, this is our observation from Group Assignment.

The task of the week is to Characterize the design rules for your PCB production process.As a part of group assignment i worked on fab mod and try to figure out following things and then later on we all go to finalised design rules.

How to use the online MODS to make files to mill your own circuit boards!

While discussing with our instructor we came to know that if the sacrificial layer is uneven then your SRM-20 will not milled the board.So we asked vikram to study more about the cut depth and i analysed the some points.